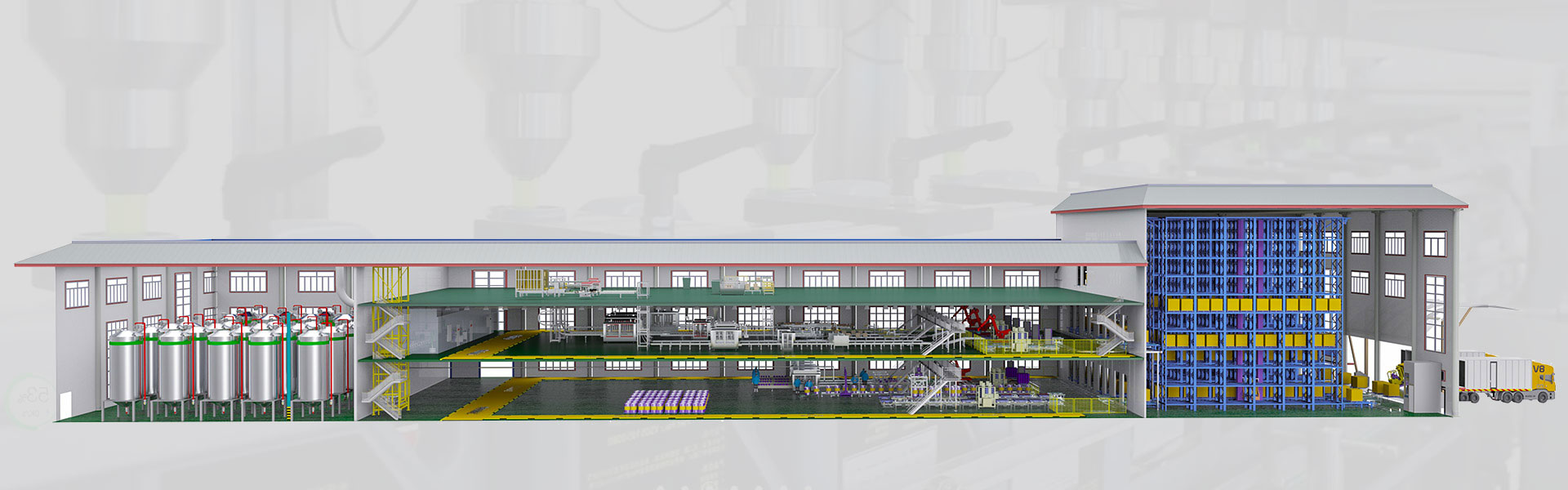

油脂自動三層空間包装生産ライン

生産ラインの土建工事の配置:3階(包装貯蔵層、1人の労働者だけが全層の瓶入れ型と箱入れ作業を担当)

2階にあります(主包装階では、1人の労働者だけがフロア全体の設備の操作とメンテナンスを担当しています)

1階(完成品トレイと完成品一時保管フロア、トレイとパレタイジングを追加する責任者は1人だけ必要)

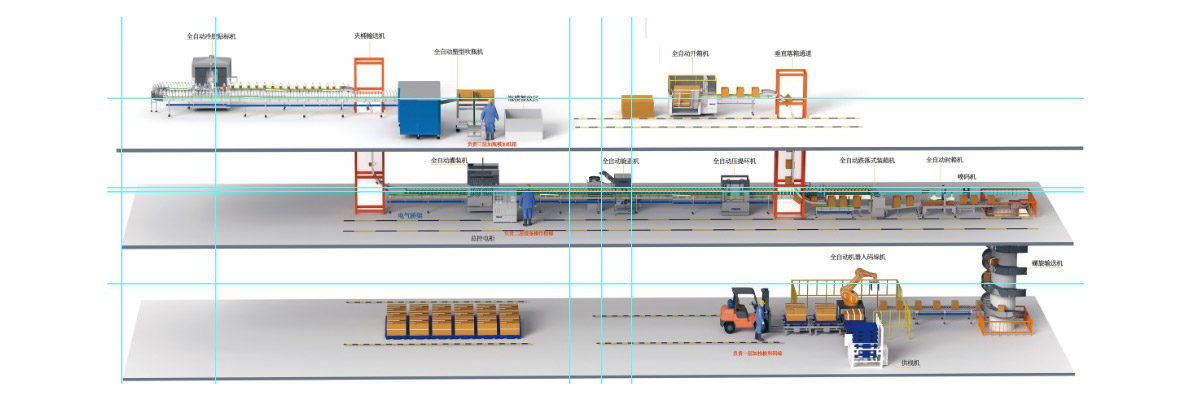

生産ライン設備構成:3階:自動開梱機、箱分解機、全自動ペットボトル吹付機、自動回転ラベラー

二階:自動充填機、自動蓋機、自動包装機、自動封口機、スクリューコンベア、総制御キャビネット。レーザーマーキングマシン、自動リングプレス

The first floor: roller conveyor equipment, stacker, fully automatic robot palletizer.

Stand-alone features:

Filling machine: This machine adopts programmable controller (PLC) and touch screen for operation control, which is convenient to use and adjust. Each filling head has a weighing feedback system that can fill the filling amount of each head.

Line fill setting and single micro adjustment. Photoelectric sensors, proximity switches, etc. are all advanced sensing components, so that no barrels are not filled, the barrel jamming machine will automatically stop and alarm. The whole machine is made according to the requirements of GMP standards. The connection of each pipeline is fast-installed. The disassembly and cleaning is convenient and quick. The contact parts and exposed parts of the materials are made of high-quality stainless steel. The whole machine is safe, environmentally friendly, hygienic and beautiful, and can adapt to various environments.

Capping machine: no damage to the bottle during the process of capping, no damage to the cap, and high efficiency of capping. It can be compared with similar foreign products. The parts have long service life, stable operation, low noise, high use range and high capping rate. The surface is polished and beautiful. It is suitable for the production line. It is a large and medium-sized packaging workshop. The ideal choice.

Pressing ring machine: This model is our company's demand in response to the market. It is aimed at the variety of handle rings in the edible oil industry on the market today, and the difficulty of automatically opening the various handle rings. After argumentation and experimentation, it is independent. Developed a pressure ring set machine for this industry, different types of handle ring automatic ring, can handle the automatic ring, upper ring and pressure ring of the edible oil industry.

Packing machine: This machine has a wide application range, small area and can be used in a single machine. It is suitable for online use of various specifications of bottle, pot, barrel automatic packaging machine and filling machine. production line. According to the requirements of the number of products packed, the machine can automatically arrange and arrange the products into the box. The products filled in the box are automatically sent to the conveyor roller for automatic unmanned production line.

Palletizing machine: It adopts two forms of robotic palletizing and traditional mechanical palletizing, and the customer configures according to his own needs;